Since large, composite seed drill sets require hydraulically powerful tractors, Pöttinger has developed a semi-combined solution that consumes less energy.

With Aerosem VT, you don’t need a heavy and powerful giant. Only 180 to 230 hp – depending on the conditions you encounter – will be enough. That is what is at stake with this seed drill, which is based on different technologies already proven in the Pöttinger range, such as Aerosem air distribution, lion’s rotary harrow and double disc seeding units.

Thanks to the trailing rotary harrow seed drill set, the lifting force required by the tractor is reduced.

Aerosem VT combines a 5m Lion 103 C-series rotary comb with 20 rotors and a 320 HP gearbox and is driven by a cardan shaft positioned under the hopper

The design of the compact 2800-liter hopper has been completely modified, with a longitudinal split. Pöttinger also designed his hopper to be easily accessible. When opened, the hood is wiped so that it does not generate a bucket or hit a large bag.

The hopper is divided in the direction of movement in a 50/50 ratio, so the seeds and fertilizer or seed alone can be combined easily. Note the presence of ultrasonic sensors to accurately indicate the load level.

A third small seed hopper is available as an option

The turbine is located at the front of the hopper and is protected by an easily accessible housing. Unused measuring wheels can be accommodated there.

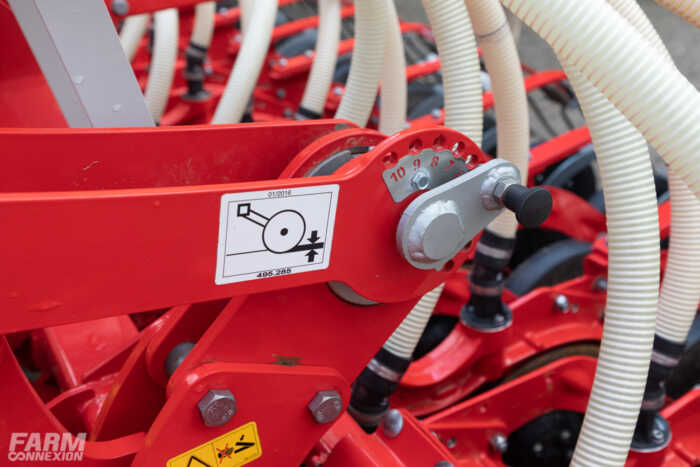

1 dispenser (ie 2 in total) per compartment. They are easy to access and have their own sensor that will calculate the pressure difference to ensure accurate flow.

The double disc element consists of two large discs that form the double disc element slightly offset (“offset” mode) to form a regular, clean groove. In addition, maintenance-free uniform-length disc support arms, with an internal slope between the front and rear rows of 30 cm, ensure efficient operation even in the presence of large amounts of plant debris. With a pressure of up to 60 kgf, vegetation is cut efficiently even at high speeds. Thus, the preservation of the seeds in the V-shaped groove is guaranteed.

Each part of the hopper has its own distribution, but then transport is carried out in one tube (“one-shot”). So each distribution is individually adjustable. Two different items can be placed in the ground with a single pass. In addition, from two application maps, sowing plots of land can be divided.

Distribution head for this new machine, designed for single seeding (descent of seed and fertilizer)

Since the rotary harrow is connected to the drum, its adjustments can be made independently of those of the seeding line. Parallelograms with levers absorb shock and allow more or less depth work.

The self-supporting tire roller (diameter 800 mm) allows certified movements with pneumatic braking on the road at a speed of 40 km / h.

Scrapers are located behind the tires.

The drill stand is located below the hopper, at the front of the frame.

|

work width (m) |

5 |

|

rotor names |

20 |

|

hopper volume (liter) |

2800 |

|

distributing hopper |

50/50 |

|

packing hole (cm) |

122 x 192 |

|

Row spacing (cm) |

12,5 |

|

Front/back row spacing (cm) |

30 |

|

pressure (kg) |

60 |

|

homogeneity |

40 km/h |

“Unapologetic pop culture trailblazer. Freelance troublemaker. Food guru. Alcohol fanatic. Gamer. Explorer. Thinker.”

![[VIDEO] Pöttinger launches Aerosem VT semi-portable headset [VIDEO] Pöttinger launches Aerosem VT semi-portable headset](https://persiadigest.com/wp-content/uploads/2021/09/1630992334_VIDEO-Pottinger-launches-Aerosem-VT-semi-portable-headset.jpg)